Intelligent High Viscosity Filling Machine For Packaging Of Water,

Emulsion, Suspension And High Viscosity Materials

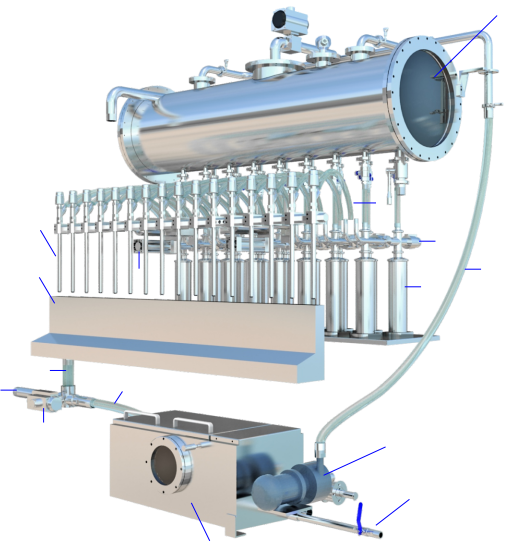

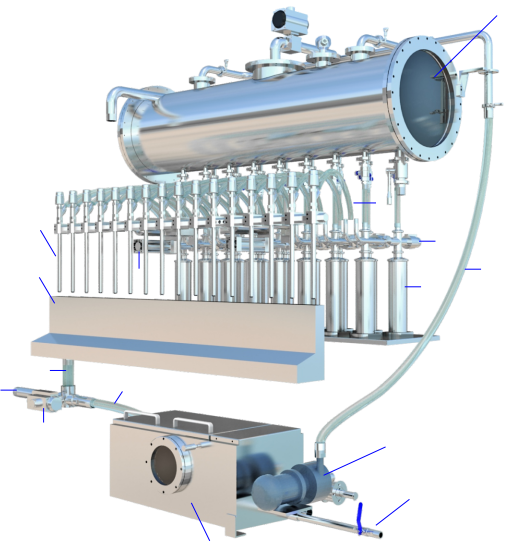

CCG1000-16TB-type intelligent high-viscosity filling machine

General information:

CCG1000-16TB is the latest generation of improved volume filling

machine.Jinchang patent design visual barrel box design, cleaning

completely no storage; intelligent one-click cleaning system, with

cleaning recycling box, replacement specifications clean carefree.

This model is suitable for packaging of water, emulsion, suspension

and high viscosity materials. The principle of servo motor drive

and volume measurement and filling is adopted to realize the high

accuracy of filling dose. Select a high-precision electronic scale

automatic weighing data transmission system, the dose adjustment is

more convenient and fast.

Technical parameters:

1 |

Fill speed | 100mL: ≤ 6,000 bottles / h 500mL: ≤ 4,000 bottles / h 1,000 mL: ≤ 3,000 bottles / h (* Water as the medium, the actual capacity fluctuates up and down

depending on customer material) |

| 2 | Bottle type | Round bottle: Φ40-95mm in diameter Bottle height is 80-230mm Square flat bottle: 40-95mm long Width of 40-95mm High of 80-230mm |

| 3 | Fill capacity | 50-1000mL. |

| 4 | Measurement accuracy | ± 1g (100mL) ± 2g (1000mL) (* with water as the medium) |

| 7 | Discharge nozzle diameter | Φ18mm. |

| 8 | Corresponding to the minimum barrel mouth inner diameter | ≥ Φ22mm. |

| 9 | Air source pressure | 0.6-0.8MPa. |

| 10 | Power Supply / Power | ~380V 50Hz/3.55KW. |

| 11 | Overall dimensions | 2485 × 1540 × 2420mm (L × W × H) |

| 12 | Weight | About 2,000 Kg |

Equipment dimension drawing:

Equipment advantages:

1, is widely used in the automatic filling of 80-1000mL bottles in

pesticides, fine chemicals, daily chemicals, fertilizers, oils and

other industries.

2, visual circular material box, the situation is clear at a

glance, circular material warehouse design, cleaning completely

without material.

3, intelligent one-key cleaning system, with its own cleaning and

recycling bin. This function is unique to Jinwang, with a patented

design.

Collect the remaining material status (replace another batch of

materials and collect the previous batch of materials):

1. "The D" cylinder opens to align the feed nozzle with the "F"

transition cycle box.

2. "Material in the A" box enter the piston cylinder through pipe

"1" and three-way valve "B". The piston reciprocation fills the

material into the "F" transition circulation box through pipe "2"

and feeding nozzle "E".

3. Connect the pipeline "3" with the pipe "4" via the "G"

"three-way valve, and the remaining material is collected at the

pipe" 4 " outlet.

. Automatic cleaning status (replace another batch of materials,

clean the previous batch of materials):

1. "The D" cylinder opens to align the feed nozzle with the "F"

transition cycle box.

2. "Material in the A" box enter the piston cylinder through pipe

"1" and three-way valve "B". The piston reciprocation fills the

material into the "F" transition circulation box through pipe "2"

and feeding nozzle "E".

3. Connect pipes "3", "5" via "G" to bring the cleaning water into

the "H" cleaning box.

4. "I" pump then hits the cleaning water in the H "cleaning box

through the pipe" 6 "to the" A " box. Cycycle cycle until the box

and pipes are cleaned.

5. Discharge the cleaning water in the "H" cleaning box through the

"J" discharge valve.

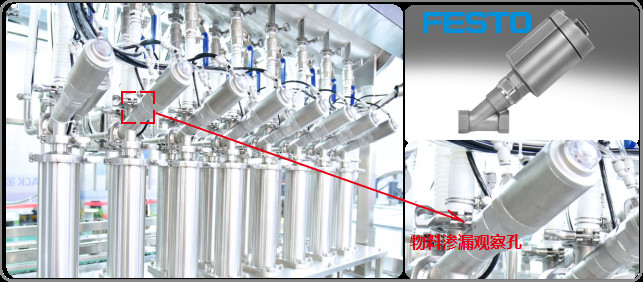

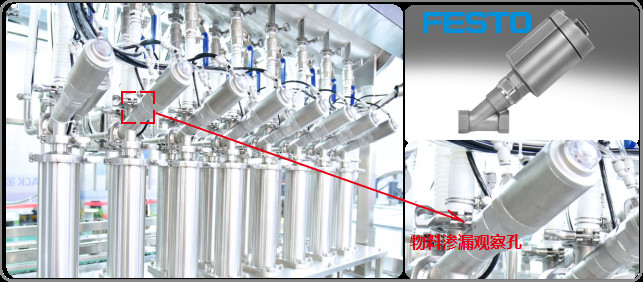

4, Jinwang and FESTO) jointly developed a new corner seat valve for

agrochemical filling industry, long life, short operation journey

one million times without leakage; modular design and maintenance

is convenient; filling time is short, 40% larger than other three

angle seat valve flow; higher safety, appearance leakage warning

and other functions

| Comparison table of FESTO angle seat valve with other general ball

valves |

| FESTO-angle seat valve | Other home general ball valve

|

| Leak life | The trip is short and 1 million times | 140,000 times |

Seal material | Seal material modified PTFE, performance stable corrosion

resistance (Better flexible and longer lived than the normal PTFE) |

Stainless steel is easy to corrosion for long time |

| Repair it | Quick maintenance (save downtime) | Difficult, with a long replacement time |

| Economy-oriented | Small gas consumption, energy saving | Large gas consumption |

| Security | Seal replacement is convenient, and material leakage warning | The leak is not easy to observe |

| Innovative design | Flow rate is 40% larger than the other three-way angle seat valves | Small flow rate and long filling time |

| Structure | Module design | Complex structure and long production cycle |

5, filling unit adopts the off-cylinder structure, which can

completely empty the materials in the material cylinder,

effectively avoid the cross-contamination of the materials, and it

is more convenient and fast to replace the sealing ring.

6,'s latest tetrafluorocarburbon technology seals improve wear

resistance and service life and reduce maintenance costs.

7, Jinwang adopts PLC programming and control, servo motor drive

synchronous belt with + drive stable double-wire bar lifting

mechanism, which ensures the high precision of piston movement

travel and realizes accurate filling.

8, uses the motor lifting filling head, which can adjust the height

of the filling head in the touch screen, quick and convenient.

9, adopts integral cast filling head of 316, good molding and

longer service life.

10, complete electric control system adopts French Schneider

configuration and integrated electric control system, which is more

stable and reliable, safe,green and low energy consumption.

11, electronic weighing system, dose adjustment with one button.

(This function is optional)

12, filling head is quickly adjusted with scale mark, adjustment

without tools, convenient and fast. Pipe and photoelectric

designation for easy maintenance and maintenance.

13, machine adopts high quality SUS304 stainless steel, better

adapt to the filling production environment, good anti-corrosion

performance and easy cleaning. Outoutsourced stainless steel and

tempered glass door cover seal the body, and the exhaust outlet

(nozzle aperture is Φ120mm diameter) can be connected to the

factory air introduction system to discharge the exhaust gas from

the filling process.

Main configuration of the equipment:

| No ial | First name "Said that." | Brand name |

1 | Programmable controller CPU. | Schneider. Schneider |

| 2 | Touch-screen | Schneider. Schneider |

| 3 | Converconverter | Schneider. Schneider |

| 4 | Servo system | Schneider. Schneider |

| 5 | Count photoelectric | SICK. Schker |

| 6 | Close proximity switch | LEUZE. Labor measurement |

| 7 | Switch on the power supply | Schneider. Schneider |

| 8 | Pressure switch | SMC. |

| 9 | Cylinder | FTEC. Eptai |

| 10 | Solenoid valve | FTEC. Eptai |

| 11 | Button | Schneider. Schneider |

| 12 | Warning lamp | Schneider. Schneider |

| 13 | Circuit breaker | Schneider. Schneider |